Exceptional Services and Maintenance Worldwide

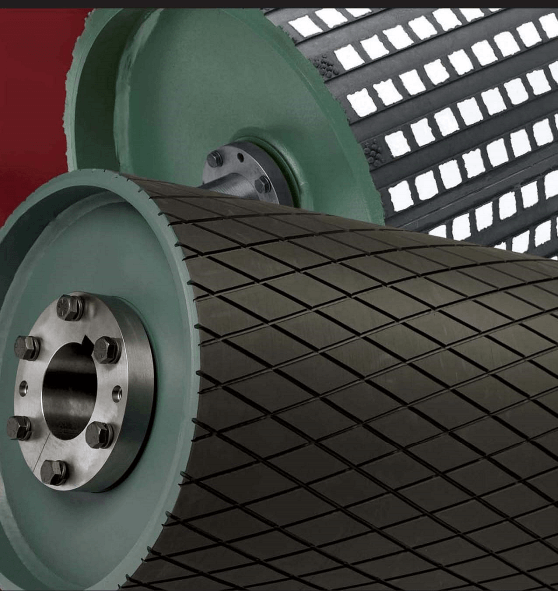

Pulley Lagging

-

Feature:

Protecting the pulley shell from wear damage, and extending the pulley’s service life. The lagging also increases the friction between the conveyor belt and the pulley to reduce belt slippage, and minimizes the buildup of bulk material, water, ice, or snow.

-

Available Lagging:

Plain, Diamond, Square, Ceramic, Slide lagging, etc

-

Typical Application:

※Diamond Pulley Lagging

Diamond pulley lagging, economical type and less wastage, enhances the friction coefficient between the pulley and belt to reduce belt slippage.

※Ceramic Pulley Lagging

Ceramic pulley lagging is specially suited for pulleys where slippage and excessive wear and tear problems make normal rubber lagging ineffective. The alumina ceramic tiles help in proper grip of the belt under wet, muddy or any other such arduous conditions.

※Slide Rubber Lagging

Slide rubber lagging is suitable for coal, mining, port, and other application environment or the conveyor system, where has a problem of belt slippage.