Exceptional Services and Maintenance Worldwide

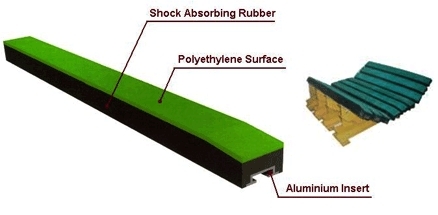

Impact Bar/Bed

-

Impact Bar:

As important cushing parts, impact bars primarily utilize high-quality, highly elastic special rubber layers to effectively absorb the impact force when materials fall, greatly reducing the impact on the conveyor belt when materials fall, truly improving the force conditions at the material discharge point. Additionally, a special UHMW polyethylene surface is used to minimize the friction coefficient between the conveyor belt and the buffer bars, providing excellent wear resistance.

-

Impact Bed:

Impact bed is a substitute tool for impact idlers.

It can absorb impact, prevent belt tearing, reduce the impact and damage of materials on the conveyor belt, avoid sharp objects from tearing and scratching the belt, and prevent material spillage and scattering.

-

Application:

Used in belt conveyor material guiding groove, blanking point below the belt.

Outstanding capability to absorbing impact and low friction coefficient.

1. Buffering for high drop material discharge points.

2. Buffering for unevenly sized material discharge.

3. Buffering for high-density material discharge.

4. Improvement of sealing in the discharge area (preventing spillage).