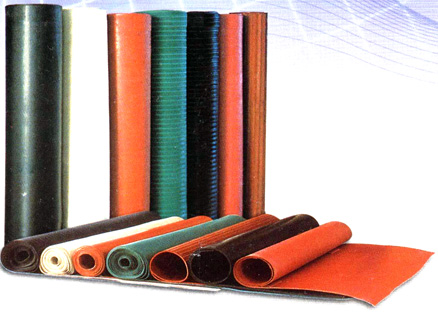

IntroductionWith the widest product range in the market, StandardA can deliver rubber sheeting and rubber matting, quickly and reliably for all areas of use.

Common applications include sealing, bearing parts and protection.

Our extensive range of rubber mattting products is suitable for most uses and is extraordinarily tough in all applications like public places as rooms, shops, restaurants, stairways, entrances, airports, buses etc. We can offer:

Smooth on both sides.

Smooth on one side + cloth impression on the other side.

Cloth impression on both sides.

Other special designs on one or both sides.

Sheets available in rolls, strips, plates o tiles.

Thickness from 0.2 mm to 50 mm.

Widths available up to 2000 mm.

General purpose rubber sheetingWith more resistant to ageing, temperature and middle pressure, water-proof, anti-shock and sealing etc. General purpose rubber sheeting mainly used as sealing gasket, sealing strip, it also could be put on the workbench or used as rubber matting. Specification Thickness: 1mm-50mm

Width: 0.5m-2m

Length:1m-30m Technical Data | Type | Specific Gravity

(g/cc) | Hardness

(Shore A) | Tensile Strength

(Mpa) | Elongation at break % | Color | | NR/SBR | 1.45 | 50±5 | 5 | 300 | black | | 1.5 | 60±5 | 4 | 250 | black | | 1.6 | 65±5 | 3 | 250 | black | | 1.7 | 70±5 | 2-2.5 | 200 | black | | NR/SBR 1 Ply | 1.6 | 65±5 | 3 | 250 | black | | NR/SBR 2 Ply | 1.6 | 65±5 | 3 | 250 | black | red

SBR Sheeting | 1.7 | 80±5 | 3 | 200 | red | grey

SBT Sheeting | 1.7 | 80±5 | 3 | 200 | grey |

SyntheticNitrile(NBR) RubberWith Excellent resistance to oils, solvents and fuels. Resistant to a broader range of aromatic hydrocarbons than neoprene. Nitrile may be blended with SBR rubber to achieve an economically priced sheet or moderately oil resistant applications. Temperature range: -30°C to +120°C, with the possibility of reaching -40°C. Technical Data Commercial Nitrile rubber | Type | Specific Gravity (g/cc) | Hardness (Shore A) | Tensile Strength (Mpa) | Elongation at break % | Color | Working temperature (°C) | |

| NBR | 1.6 | 70±5 | 3 | 200 | black | -20/90 | | 1.55 | 65±5 | 4 | 250 | black | -20/90 | | 1.5 | 60±5 | 5 | 250 | black | -20/90 | | 1.4 | 70±5 | 7 | 300 | black | -20/90 |

High quality Nitrile rubber | Type | Specific Gravity (g/cc) | Hardness (Shore A) | Tensile Strength (Mpa) | Elongation at break % | Color | Working temperature(°C) | |

| NBR | 1.16 | 50±5 | 7.5 | 450 | black | -30/100 | | 1.19 | 60±5 | 8.5 | 400 | black | -30/100 | | 1.2 | 65±5 | 8.5 | 400 | black | -30/100 | | 1.21 | 70±5 | 12.5 | 250 | black | -30/100 | | 1.28 | 80±5 | 12.5 | 150 | black | -30/100 |

Neoprene(CR) RubberExcellent mechanical and abrasion properties even without reinforcing fillers;

Good resistance to heat, ozone and weathering.

Resistance to chemicals; resistant to inorganic chemical products , except oxidising acids and halogens.

Moderate resistance to aliphatic hydrocarbons Technical Data | Type | Specific Gravity (g/cc) | Hardness (Shore A) | Tensile Strength (Mpa) | Elongation at break % | Color | Working temperature (° C) | |

| Commercial CR | 1.6 | 70±5 | 3 | 200 | black | | | 1.5 | 70±5 | 5 | 250 | black | | | 1.4 | 50±5 | 5 | 300 | black | | | High quality CR | 1.35 | 60±5 | 13 | 300 | black | -40/100 |

EPDM RubberExcellent resistance to ozone, sunlight and oxygen.

Excellent resistance to acid, alkali and ketones.

Excellent inherent high and low temperature ranges. Typically -45°C to +120°C for standard compounds. Technical Data | Type | Specific Gravity (g/cc) | Hardness (Shore A) | Tensile Strength (Mpa) | Elongation at break % | Color | Ozone Resistant

30°C x 72H x 20% | |

| EPDM | 1.6 | 70±5 | 3 | 200 | black | 50pphm | | 1.5 | 70±5 | 5 | 300 | black | 50pphm | | 1.35 | 60±5 | 5 | 300 | black | 200pphm | | 1.3 | 50±5 | 5 | 300 | black | 50pphm |

Butyl RubberExcellent resistance to ozone, oxidation and sunlight.

Has very low resilience which makes it ideal for vibration damping and shock absorption applications.

Resistance to chemicals; resistant to most inorganic products. Highly resistant to mineral acids, alkalines and aqueous acids. Technical Data | Type | Specific Gravity (g/cc) | Hardness (Shore A) | Tensile Strength (Mpa) | Elongation at break % | Color | Working temperature

(° C) | |

| Butyl | 1.5 | 70±5 | 5 | 300 | black | -30/130 | | 1.4 | 60±5 | 5 | 300 | black | -30/130 | | 1.3 | 50±5 | 5 | 300 | black | -30/130 |

SpecialHypalon Sheeting - Excellent resistance to oxidation and has outstanding resistance to atmospheric conditions an in particular strong sunlight and ozone.

- CSM compounds resist fire and are self extinguishing when the flame is removed.

- Resistance to chemicals; resistant to most inorganic chemical products, good resistance to general acids, oils and greases.

Technical Data | Type | Specific Gravity (g/cc) | Hardness (Shore A) | Tensile Strength (Mpa) | Elongation at break % | Color | Working temperature

(º C) | |

| Hypalon | 1.35 | 50±5 | 6 | 400 | black | -30/120 | | 1.45 | 60±5 | 6 | 350 | black | -30/120 | | 1.25 | 60±5 | 11 | 400 | black | -30/120 |

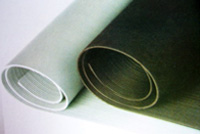

Silicone Rubber sheet I. Description:

- Silicone rubber is good on surface, high stability and durable.

- Excellent in softness, elasticity, insulation, air tightness, ozone resistance, weather fastness and alcohol, animal/plant oil and polar organic resistant.

- Silicone rubber is widely used for membrane press of solar energy lamination machine, wooden and glass industry.

II. Application:

1. Silicone Rubber Membrane/Diaphragm for the solar energy laminating machine

| Hardness (Shore A) | Tensile Strength (Mpa) | Elongation at break % | Tearing strength (N/mm) | Thickness (mm) | Width (mm) | Temperature (ºC) | |

| 50-70 | ≥ 8.5 | ≥ 550 | ≥ 30 | 1-10 | 2800 | -60 ~ 230 |

2. Silicone Rubber for wooden industry

| Hardness (Shore A) | Tensile Strength (Mpa) | Elongation at break % | Tearing strength (N/mm) | Thickness (mm) | Width (mm) | Temperature (ºC) | |

| 40-50 | ≥ 8 | ≥ 550 | ≥ 32 | 1-10 | 2900 | -60 ~ 230 |

3. Silicone Rubber for glass industry

| Hardness (Shore A) | Tensile Strength (Mpa) | Elongation at break % | Tearing strength (N/mm) | Thickness (mm) | Width (mm) | Temperature (ºC) | |

| 50±5 | ≥ 7 | ≥ 350 | ≥ 23 | 1-10 | 2900 | -60 ~ 230 |

Viton Rubber - Viton is serviceable in continuous heat of up to 250º C and intermittent heat of up to 300º C.

- Satisfactory resistance to low temperatures of typically -20º C and - 40º C by use of special grades.

- Good flame resistance and are usually self extinguishing upon removal of flame source.

- Have excellent resistance to oxygen, ozone and natural weathering.

Technical Data | Type | Specific Gravity (g/cc) | Hardness (Shore A) | Tensile Strength (Mpa) | Elongation at break % | Color | |

| Viton | 1.9 | 75±5 | 7 | 150 | black |

Natural Gum Sheeting- Good gasket material due to excellent physical properties such as resilience, tear strength and wear resistance.

- Natural rubber is used effectively as sand and shot blast curtain material because of it's high abrasion resistance and resilience.

Technical Data | Type | Specific Gravity (g/cc) | Hardness (Shore A) | Tensile Strength (Mpa) | Elongation at break % | Color | Abrasion (mm3) | |

| Natural Gum | 1.3 | 70±5 | 12 | 500 | Tan, brown, red, orange, black | 150 | | 1.3 | 60±5 | 14 | 500 | 120 | | 1.1 | 40±5 | 14.5 | 500 | 110 | | 1.04 | 40±5 | 16 | 600 | 80 | | 1.04 | 40±5 | 22 | 600 | 80 |

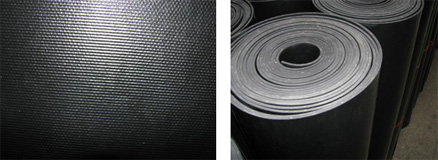

Rubber mattingPuttern Rubber Matting

Fine rib matting

Thickness:2.5-6mm; Width:1.5m |

Corrugated matting

Thickness:2.5-6mm; Width:2.0m | | | |

Thick rib matting

Thickness:2.5-6mm; Width:2.0m |

Flat rib matting

Thickness:2.5-6mm; Width:2.0m | | | |

Stud matting

Thickness:3-6mm; Width:1.5m |

Small stud matting

Thickness:3-6mm; Width:2.0m | | | |

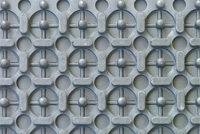

Checker matting

Thickness:2.5-6mm; Width:1.5m |

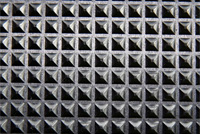

Pyramid matting

Thickness:3-10mm; Width:1.2m | | | |

Rhomboid matting

Thickness:3-6.5mm; Width:1.5m |

Rice matting

Thickness:3-10mm; Width:1.2m |

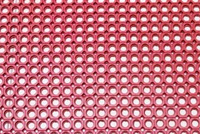

Anti fatigue Rubber Matting

Thickness:16; Width:914m Length:914 |

Thickness:16; Width:914m Length:914 |

Thickness:16; Width:914m Length:914 | | | | |

Thickness:20; Width:920m Length:920 | |

Agriculture Rubber Matting

Cow matting 01

Thickness:8-25mm; Width:2m |

Cow matting 02

17mmx1220mmx1830mm | | | |

Hose matting

Thickness:2.5-6mm; Width:1.5m | | | | |

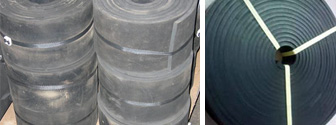

Skirting RubberDescription:

Skirting rubber is a general purpose rubber used mainly in the mining industry as a side skirt on conveyor belt systems to prevent the materials falling down. It is available in full width slabs up to 2000 mm wide and also pre-cut skirting strips.

STD 60 Duro

A general purpose grade of natural rubber used for many quarrying and mining applications in dust and spillage control. Soft 40-50 Duro

A softer grade natural rubber, with good tensile and elongations properties, it is ideally suited for conveyor skirting applications where belting wear is of concern. The rubber is also used where a flexible, but abrasive resistant seal is required. Specification:

Width: 76 -- 2,000 mm

Thickness: 2 -- 50 mm

Roll length: 3 -- 30 m

Parameter of rubber:

Tension strength: Normally 2.5mpa -- 6mpa,

Elongation: ≥ 250%, 300%

Hardness: 50, 60, 70 shore A

Other specification available as special order.

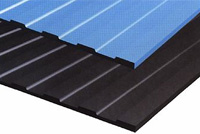

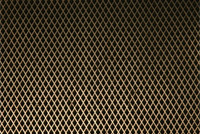

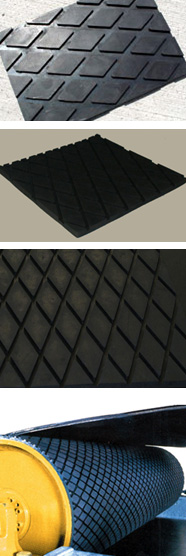

Pulley Lagging | Conveyor Belt when slips causes significant damage to the drive pulley and the belt. Such damages are not only expensive to repair, but also time consuming and cause enormous loss due to down time. The life span of a conveyor system primarily depends on its being suitably equipped for the specific application and the standard of servicing and maintenance. The conveyor systems often have to perform in the most difficult conditions.For example rain and sludge, which cause slippage between the conveyor belt and pulleys because of the friction co-efficient between the two going down very low. Pulley Laggings, with specially developed rubber materials and their patterned surfaces have proved to be very effective in water shedding, preventing material build up and controlling belt slippage. Diamond Profile black lagging is ideal for small diameter pulleys on systems with black conveyor belt.

It prevents belt from slippage (in particular when water is present) and increase the drive traction of the pulley.

For Drive pulleys, a friction lagging should always be used.

The type of friction lagging should be selected by the customer according to its application.

Availability

Widths ranging from 1000mm - 2000mm

Thickness: 8mm - 12mm.

Length: 10M-20M

Technical Data: Tensile Strength:7MPA Density:1.45g/cc Elongation:300%

Other specification available as special order. |

Chute LiningChute Lining is designed to be an integral part of a conveyor system to protect and cushion the chute from the material being handled Main features: - Protects chute from wear and corrosion

- High wear and cut resistance

- High impact resistance

- Significantly reduces noise pollution

- Available in various sizes and thicknesses

- Reduces build-up and facilitates free flow

- Special applications available: abrasion-resistant, chemical, heat, etc

- Site or factory fitted

|